There's no doubt that solder installation is an art, however it also causes many concerns. How often have you suffered from noxious fumes on a jobsite? Has time-intensive soldering work delayed schedules or caused cost overruns? Have you been concerned about potential fire hazards or work safety and the additional costs that come along with those concerns?

Now, you can alleviate those challenges with the push of a button. With Press, you can safely install a complete, high-quality system in less time than with traditional soldering methods. Keep reading to learn more about the advantages of Press Vs. Soldering.

Here's a list of some of the features you could be taking advantage of while using press:

1. Design

Here are just a few reasons why the press system design makes a great alternative to soldering:

- Hydraulic press tools "crimp" joints in copper tubes with press fittings and valves. The result is a permanent, leak-free seal in just seconds.

- The need for gas tanks and fire extinguishers is eliminated.

- High skills or tenured labor pool is not required.

- Installs wet or dry, with no system down time.

- Allows for dry-fit system

- Assemble before crimping.

2. Safety

Safety is always a concern when working on jobsites with solder. With press, installation is much safer for these reasons:

- Installation is completely flame free; no noxious

fumes or harmful emissions are present with the press system.

fumes or harmful emissions are present with the press system. - With no fire hazard, you can safely install the system in occupied spaces or during retrofit jobs.

- The system's simplified design means less clutter on the jobsite, faster clean up, and no waste from flux, solder, torch and gas cans.

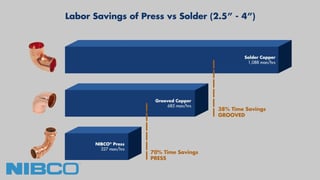

3. Time Savings

We all know that time is money, and the press system knows it, too. Here are some great time-saving features of the press system:

- Press system installation takes as little as 30 seconds requiring as much as 95% less time to install than with solder and grooves.

- You can install in a wet or dry system with no downtime, saving you time and money.

- Features a mechanical joining system for copper tube and fittings that is faster and more efficient, saving time on labor cost and installation.

As you can see from just the short list above, there are many benefits to choosing press over solder that can help you save time and money. Improve the quality and work conditions on your jobsite by choosing a safer, faster solution to your installation needs.